Product Center

Home > Product Center > drawing machine > Slip Type Rod Breakdown Drawin > LHD450 Slip Type Double Heads Wire Drawing Machine

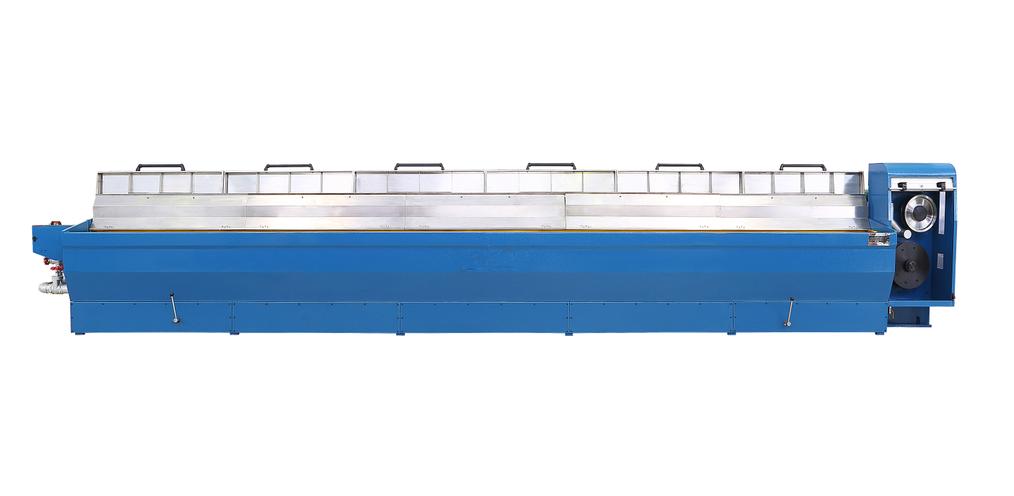

LHD450 Slip Type ,Rod Breakdown Drawing Machine(with Continuous Annealer)

Usage

The machine is used for drawing EC copper rod from Φ8.0mm to Φ1.5-3.5mm which can be annealed is wound by automatic double spooler or pack coiler.

Main Performance Characteristics

◎The main drawing machine is whole structure and whole machinery process, high precise, low vibration, stable running and long life span;

◎Drawing capstan by full immersion in drawing lubricant for cooling ,drawing die holder by spraying, the overall double-layer structure of drawing base with an overflow hole, prevent liquid splashing liquid and ensure the site clean; a four-way mechanical sealing is used between drawing base and gearbox. Drawing lubricant and gear oil do not mix with each other.

◎The drawing capstan with reasonable structure, assemble and disassemble more convenient by accurate position;

◎Two wires drawing machine efficiency is double than one wire drawing machine, but the energy consumption is 8-10% lower than one wire drawing machine

◎Cantilever type pay off stand for copperrod with air cylinder position fix system with rod stop system if rod knotted.

◎Three-phase alternating current annealing, high efficiency; conductive wheels using special cooling structure, easy maintenance; achieve near-zero speed annealing, and annealing high quality.

◎Accumulator tension controlled by pendulum rod, with less resistance but more sensitive.

◎Automatic double spooler, non-movable wire traverse, tidy and stable; central push structure, bobbin change wire pressure and loose structure, 100% successful push rate, and high successful bobbin change rate.

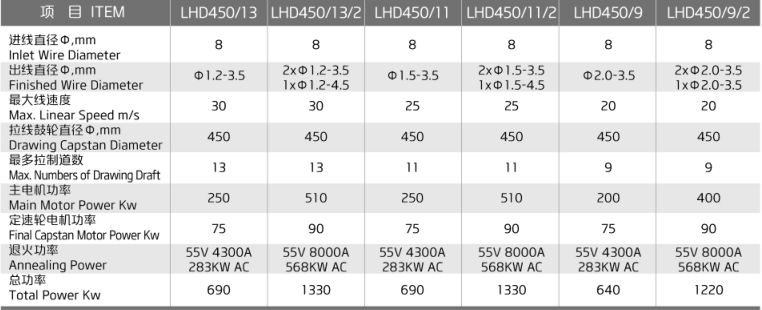

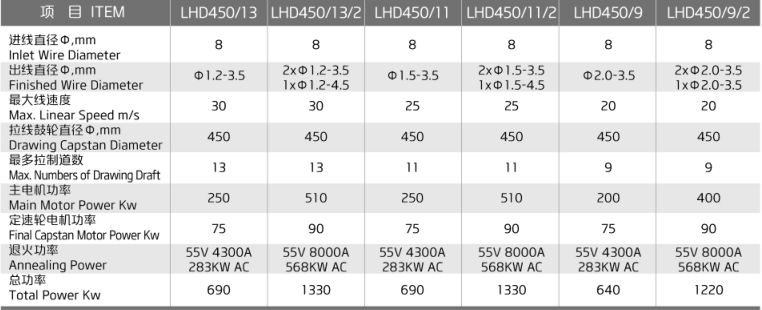

Main Technical Parameter

The machine is used for drawing EC copper rod from Φ8.0mm to Φ1.5-3.5mm which can be annealed is wound by automatic double spooler or pack coiler.

Main Performance Characteristics

◎The main drawing machine is whole structure and whole machinery process, high precise, low vibration, stable running and long life span;

◎Drawing capstan by full immersion in drawing lubricant for cooling ,drawing die holder by spraying, the overall double-layer structure of drawing base with an overflow hole, prevent liquid splashing liquid and ensure the site clean; a four-way mechanical sealing is used between drawing base and gearbox. Drawing lubricant and gear oil do not mix with each other.

◎The drawing capstan with reasonable structure, assemble and disassemble more convenient by accurate position;

◎Two wires drawing machine efficiency is double than one wire drawing machine, but the energy consumption is 8-10% lower than one wire drawing machine

◎Cantilever type pay off stand for copperrod with air cylinder position fix system with rod stop system if rod knotted.

◎Three-phase alternating current annealing, high efficiency; conductive wheels using special cooling structure, easy maintenance; achieve near-zero speed annealing, and annealing high quality.

◎Accumulator tension controlled by pendulum rod, with less resistance but more sensitive.

◎Automatic double spooler, non-movable wire traverse, tidy and stable; central push structure, bobbin change wire pressure and loose structure, 100% successful push rate, and high successful bobbin change rate.

Main Technical Parameter