Product Center

Home > Product Center > Key Products Recommended > Rigid Frame Stranding Machine > JLK 630 Rigid Frame Stranding Machine by Separate motor

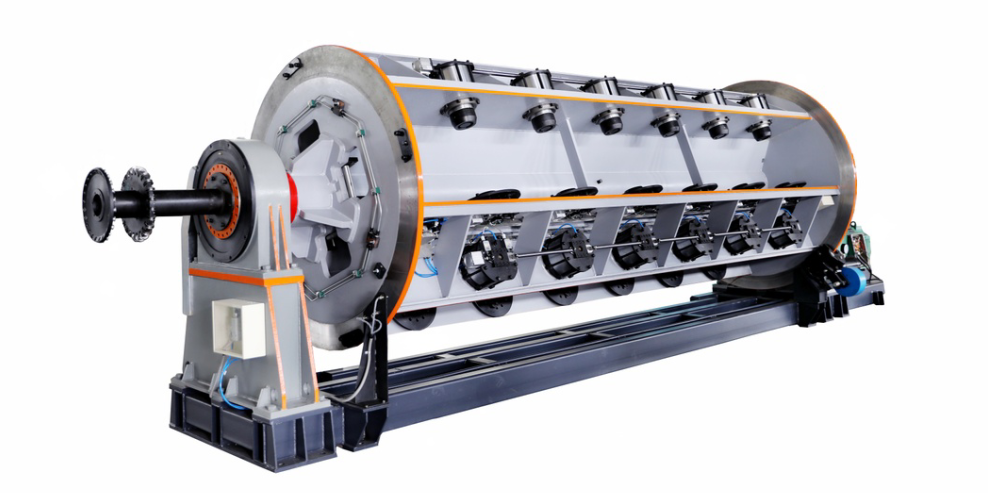

JLK 630 Rigid Frame Stranding Machine by Separate motor

(Lumped loading / unloading for bobbins)

(Lumped loading / unloading for bobbins)

Usage

The machine is used for stranding compacted sector conductor of long length aluminum alloy, bare aluminum, bare copper, ACSR, round conductor with compacting of Pre-forming and drawing process,conductor of long length, big cross section XLPE insulated cable.

Main Performance Characteristics

◎ Each cage and capstan wheel are driven by separate motor, the pitch can be adjusted freely.The machine is used for stranding compacted sector conductor of long length aluminum alloy, bare aluminum, bare copper, ACSR, round conductor with compacting of Pre-forming and drawing process,conductor of long length, big cross section XLPE insulated cable.

Main Performance Characteristics

◎The cage are transmission by reducer from motor instead of by timing belt; the cage loading/unloading is driven by cage motor of low speed mode;

◎The spindle for fixed bobbins on the cage is open by pneumatic and clamped by spring device with mechanical safety lock system; and increase the cage rotate speed without the air package system.

◎With position point fixing design to guarantee the accurate match for the cage and bobbin loading and unloading system ,the loading and unloading device can be motorized or hydraulic.

◎Wire-break sensor will be feedback to the power system, can achieve the energy-saving purposes,

◎Electric system can be under remote mode; and wire break can be displayed on the touch screen show the bobbin position on the cage;

◎Intelligent controller system: with energy meters, DP communication, on-site checking PLC system, on-line monitoring; the data can be uploaded to the host by PLC;Through internet can achieve: on-site production data reading and ladder diagram analyse, remote diagnosis, program upgrades, remote maintenance, commissioning guidance and so on.